Wood Or Wood Not. What Is The Best Axe Material?

Wood is a traditional, versatile material for an axe handle, but are the alternatives just as good, or even better?

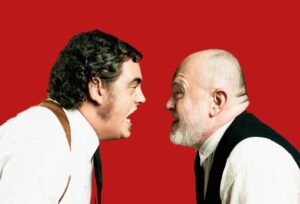

Axe handles, or hafts, traditionally are made of wood, but metal and fibreglass alternatives offer some advantages too. This Bury the Hatchet debate discusses the relative benefits of whether wood or non-wooden materials make the best handle.

I am firmly in favour of wooden axe handles. Axe handles have been made from wood since about 6000 BCE.

Wood such as hickory or ash (due to their strong, but flexible properties) is still the most common material used today. When most people think of an axe, they think of a wooden axe

Most people probably do think of wooden-handled axes, but times change. These days, for everyday use, metal and fibreglass make a far more sensible alternative for axe handles than wood.

Metal and fibreglass handles will put up with a great deal more mistreatment than wood. They are therefore the best option for axe throwing, which necessarily increases the risk of mistreatment, particularly when used by beginners.

Sure, throwing creates additional stress on an axe. Wood handles are more likely to break if thrown, rather than if used simply to chop wood, particularly if thrown by non-experts. However, good axe throwing instruction and technique will reduce breakages.

Strapping the handle with hockey or pvc tape, or coating it with boiled linseed oil, will also help.

Many expert throwers will use the same wooden axe regularly for years.

Fair enough. Metal and fibreglass handled axes may be more use to throwers that are new to the sport rather than experts. However, axe throwing as a social activity has grown rapidly over the last twenty years or so. This means there are increasingly a large number of first-time throwers – and inevitably a large number of mishaps.

Rather than have a pile of broken wooden handles, metal or fibreglass handles could provide a more robust alternative and far less waste.

Metal and fibreglass axes can also splinter and break. If a metal or fibreglass fixed head axe breaks, then the axe is usually thrown away.

True, sometimes, but metal and fibreglass axes are far more robust and generally last much longer than wood.

They also cost about he same for comparable wooden axes, so are therefore more cost effective in the long term.

It is still a waste though. Wood is a sustainable crop and wooden handles can be replaced relatively easily if they do break. The metal axehead can be continually reused wit a new handle.

Changing a wooden axe handle is a lot of work though. A lot of the time they are simply thrown away in any case.

It is hard to replace a fixed head axe, but it is commonly done, especially for larger and/or more expensive axes. (Ok, cheap kindling hatchets may not always be re-hung).

Alternatively, a slip fit axe (ie where the axe head is not permanently fixed to the handle) is extremely simple to replace. It is standard practise to replace broken slip fit handles.

It is also more than just about resilience. A smooth wooden handle does enable an axe to slip out of your hand easily while throwing.

Day-to-day fibreglass axes tend to have grips that are purposely intended not to fly out of your hand. An advantage for chopping but not for throwing! They also tend to be poorly balanced for throwing (with more weight in the handle).

That is true for fibreglass ‘wood choppers’. However, there are now fibreglass axes that have been specifically designed for throwing. For example, both the big indoor hatchet throwing organisation, IATF and WATL, sell fibreglass throwers aimed at beginners.1

It is also possible to get replacement fibreglass handles for slip fit axes (such as the Cold Steel Hawks).2 The fibreglass can even be sanded and shaped to some extent to make it fit for purpose.

It is much easier to shape a wooden axe though, even with just basic carpentry skills. They can be shaped to make it perfectly balanced to suit a particular throwing style.

Agreed, but more often people buy axes off-the-shelf anyway.

There are many finely crafted wooden handled throwing axes on the market. In fact, the majority of made-for-throwing axes have wooden handles.

Metal axes are also usually harder to release as they often have some sort of rubber grip to make it less likely to fly out of your hand when chopping!

Although it is common to have a rubber grip, metal axes can be just metal. There are a number of metal axes on the market specifically made for throwing. The problems of a rubber grip (eg harder to release, rubber getting damaged from throwing) can be overcome by taping them up with hockey tape or similar.

The supposed advantage of wooden handles being easier to release is negated by the fact that many wooden handles are taped up to help reduce the wood breaking (as you mentioned before).

Yes, house axes maybe taped up, but it is rare for expert/competitive throwers, who like the feel of the smooth wood for release. It is unusual to see metal or fibreglass axes in competitions these days.

It may not be the usual practice, but you could compete with a non-wooden axe in a range of competitions.

Some axe throwing competition organisers will only allow wooden handles. but there are plenty that do not care about what the handle is made of as long as the axe meets their specifications. These include: WATL, EuroThrowers, Blade Aces and UKAT.

And, of course, not everyone want to compete!

Even if you are not competing, anecdotal evidence suggests that social throwers like the look and feel of wooden handles over other alternatives.

While that is evidently true, axe throwing as a sport is a relatively modern activity and therefore using a more modern material would seem a reasonable move?

Other sports have developed more high tech materials to push the boundaries of their sport. There is no reason to think that specialist axe throwing axe makers will not do the same!

That may true, in time, but the current focus is definitely on getting the most out of wooden handles.

I think that we have achieved consensus on one thing then: many throwers will often simply prefer wood because of a nostalgic view that wood is the traditional material!

We do agree to a limited extent. Maybe there is an element of nostalgia, but perhaps, more accurately, it should be described as a sense of tradition. For better or worse, throwers (beginners or experts) seem to find a wooden handled axe provides a greater affinity with the kind of lumberjack spirit they expect from axe throwing.